SEMI EDA Standard Compliance Solution

SEMI EDA STANDARD

What is EDA Standard?

With the continuous advancement of semiconductor manufacturing technology and increasing complexity in equipment design and processes, the need for high-quality data (manufacturing big data) for equipment analysis has become essential.

Since the early 2000s, the SEMI Global Information & Control Technical Committee has developed a dedicated protocol for reliable equipment data analysis, independent of the SECS/GEM* protocol, by establishing a separate data channel for high-volume, high-frequency data. This protocol was named the EDA (Equipment Data Acquisition) Standard.

The EDA Standard has evolved through Freeze.1 in 2005 and Freeze.2 in 2010, with the development of Freeze.3 currently on the horizon.

Notably, EDA not only facilitates high-volume, high-frequency equipment data collection but also serves as a data service platform utilizing multi-session and multi-client web service technologies, enabling a new data ecosystem for diverse analytical applications.

*SECS/GEM: A semiconductor standard communication protocol designed for equipment control (Semiconductor Equipment Communication Standard & Generic Equipment Model).

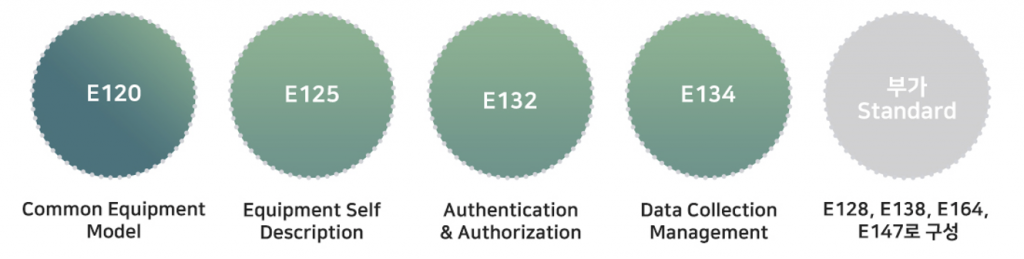

SEMI EDA Freeze.2

SEMI EDA Freeze.2

| Feature | SECS/GEM | EDA |

|---|---|---|

| Data Rates | 10 variables per Chamber 300 values/sec |

50 variables per Chamber 5000 values/sec |

| Event Data | Process Event | Process Event Physical, Mechanical Event |

| Self-Describing | Only Data ID | Equipment structure described as data |

| Secure Communications | Only Equipment Host | Security through Admin e-Diagnostic |

| Configuration | Socket | HTTP (SOAP XML) |

ANTICIPATED EFFECTS

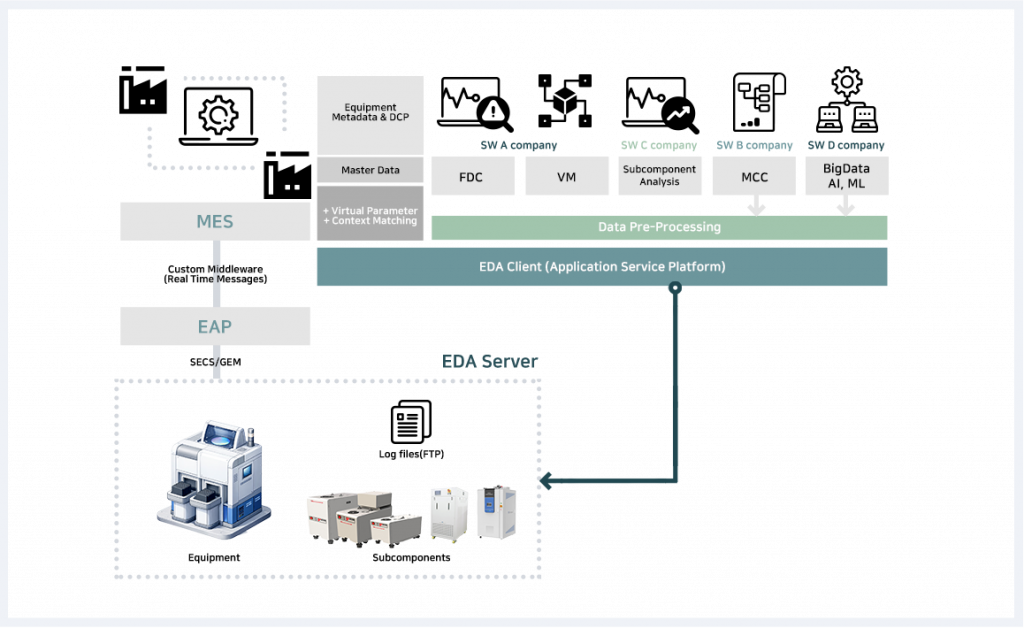

EDA Client = Data Service Platform

We enable a real-time data pipeline that quickly and efficiently transforms data collected from manufacturing sites into context-based datasets tailored to the needs of analytical systems.

ANTICIPATED EFFECTS

EDA Client = Data Service Platform

We enable a real-time data pipeline that quickly and efficiently transforms data collected from manufacturing sites into context-based datasets tailored to the needs of analytical systems.

Flexible data collection

Flexible Data Collection

Flexible data collection enabled through Data Channel separation.

Standardize equipment reference information

Standardization of Equipment Reference Information

Consistent data utilization across various analytical systems is enabled through integrated management of equipment reference information based on EDA.

Acquisition of more high-quality data

Acquisition of More High-Quality Data

The specification and management of required data become more efficient, enabling the acquisition of more high-quality data.

Improve the accuracy of analytical results

Improvements in Analytical Accuracy

Removing inter-system data dependencies enables smoother demand data delivery and more accurate analysis results.

OPC UA Standard Compliance Solution

OPC UA STANDARD

What Is OPC UA Standard?

OPC UA (OPC Unified Architecture) is a standardized data communication protocol between industrial automation devices and systems. It is a next-generation standard that moves beyond the Windows/COM dependency of OPC Classic, offering platform independence and enhanced security.

- Platform Independence: It runs not only on Windows but also on Linux and embedded systems, and it is firewall-friendly because it is based on TCP/IP transport protocols.

- Enhanced Security:It supports authentication, encryption, and digital signatures as standard, and through information models it can convey not only raw data but also its meaning and structure.

- Key Services:It reads and writes real-time data via Read/Write, executes device control commands through Method Call, and efficiently monitors data changes using Subscriptions. The Address Space is a core concept that organizes information in a hierarchical structure and forms the system’s information model.

Brief OPC UA

OPC Classic vs. OPC UA

| Category | OPC Classic | OPC UA |

|---|---|---|

| Platform | Windows only | All OS |

| Security | None | Encryption / Authentication |

| Firewall | Complex (multiple ports) | Simple (single port) |

| Data Model | Simple tags | Hierarchical objects |

| Scalability | Tens of thousands of tags | Millions of tags |

| Cloud | Difficulty | Native support |

| Developer Ecosystem | Legacy | Modern |

| Standardization | Limited | Companion Specs |

| Maintenance | Difficulty | Easy |

| Future Outlook | Risk of EOL | Continuous development |

- Platform Independence

- –Performance bottlenecks caused by architectural limitations of COM

- –Issues such as memory leaks and response delays occur frequently

- Built-in Security

- –Mutual authentication based on X.509 certificates

- –Transport encryption: supports AES-128/256 and RSA

- –Message integrity: SHA-256 signatures

- –User authentication

- Rich Information Model

- –Hierarchical Address Space – object-oriented modeling

- –Support for complex data types

- –Rich metadata

- –Ability to represent semantic relationships

- Improved Performance

- –Can handle tens of thousands to millions of tags

- –Multi-threaded architecture – parallel processing

- –Subscription-based – efficient data delivery

- –Data compression options and chunked transfer

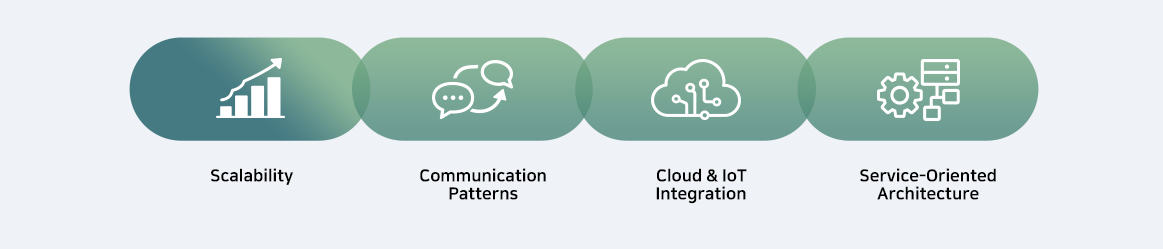

OPC UA Solutions

OPC UA Clients & Servers

Manufacturing Big Data Platform

HIGHLIGHTS

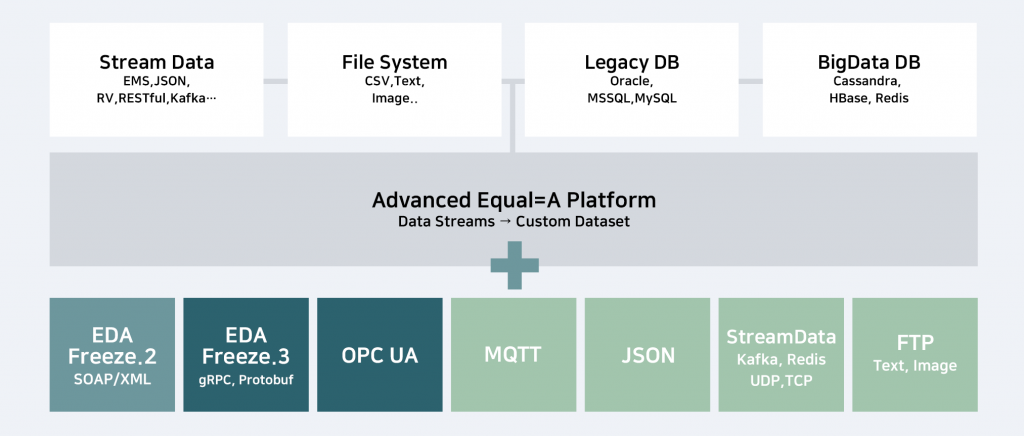

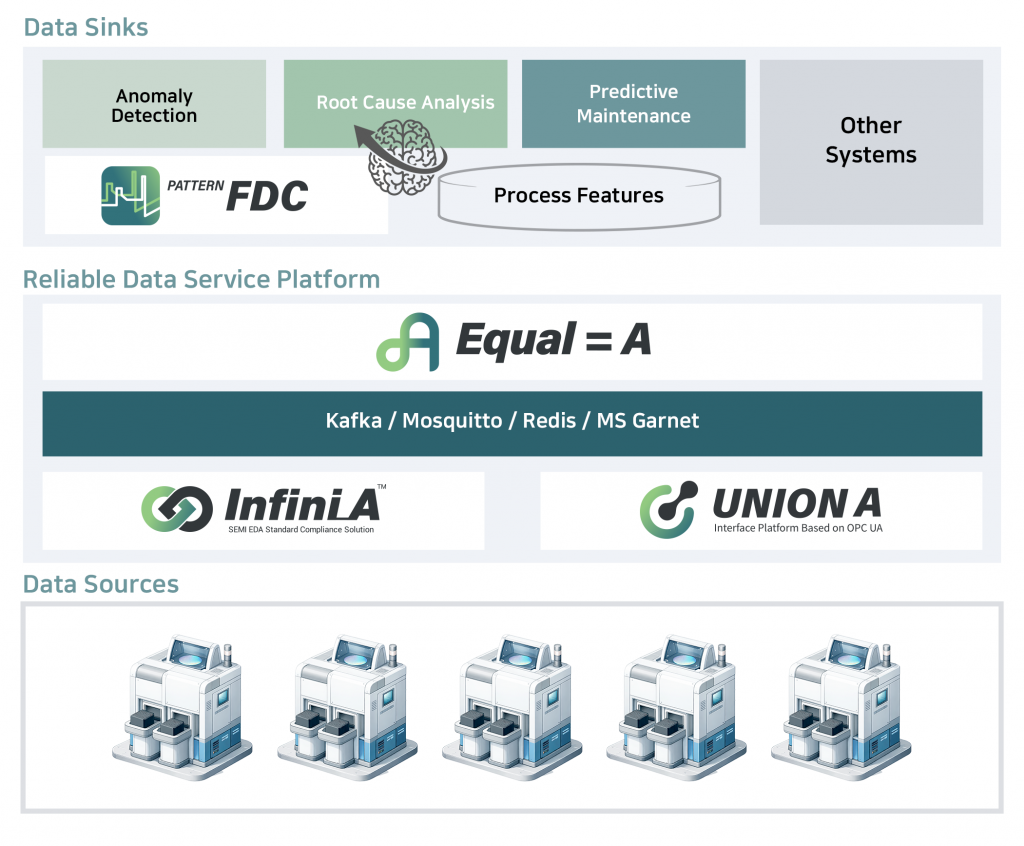

Plug and Play Data Service

We enable a real-time data pipeline that efficiently transforms data collected from manufacturing sites into context-based datasets tailored to the requirements of analytical systems.

- Support for integrating various industry-standard interfaces

- Support for interoperability between legacy interfaces

- Improved reliability of source data

- Reduced development time and cost for data collection and preprocessing

- Establishment of an efficient big data analytics foundation

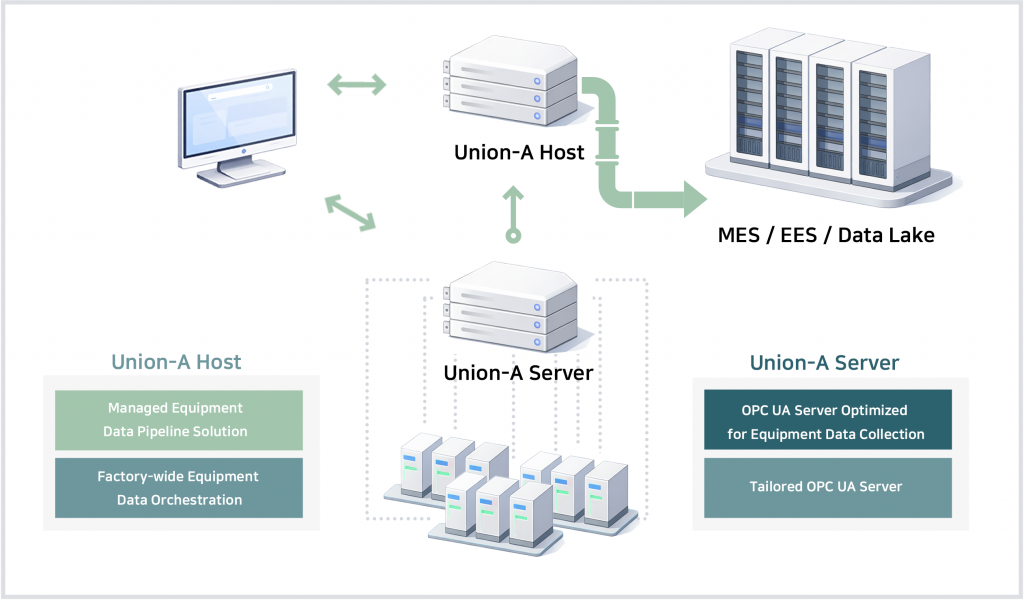

ARCHITECTURE

Plug and Play Data Service Platform

ARCHITECTURE

Plug and Play Data Service Platform

DX/AX PLATFORM ROADMAP

Solution Architecture

DX/AX PLATFORM ROADMAP

Solution Architecture

Accelerate Your AI Projects

Key Takeaways

Standardization Benefits

Key Takeaways

Standardization Benefits

Minimized Costs

In sites where an EDA and OPC UA server are already in place, no additional development investment is required for data collection.

Minimized Deployment Time

By leveraging Doople’s pre-built factory-wide host product, you can establish a data collection and real-time processing environment without any additional development.

Use of Proven, Validated Data

You can directly benefit from the data quality secured through on-site process validation.

Flexible Data Configuration

With only standard-compliant Data Collection settings, you can flexibly collect all data provided by the equipment.

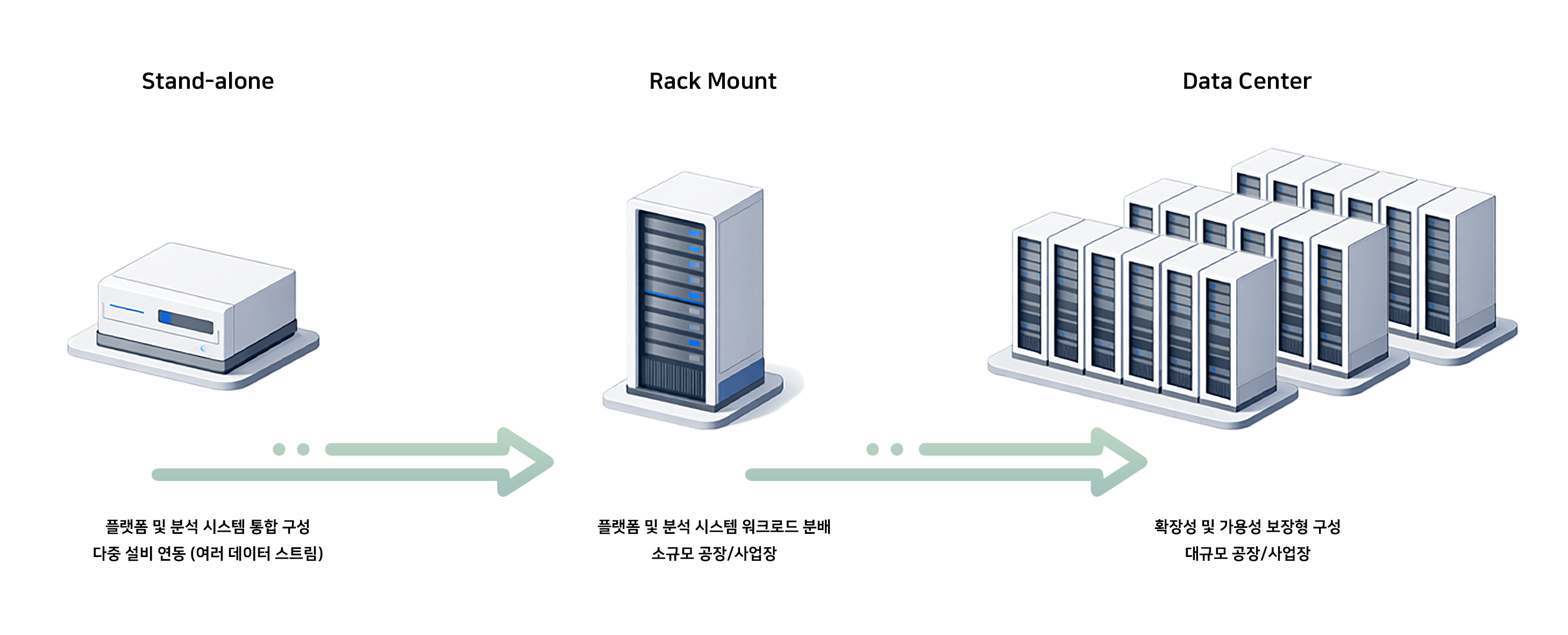

SCALABLE SYSTEM CONFIGURATIONS

Start Small and Build it up

SCALABLE SYSTEM CONFIGURATIONS

Start Small and Build it up

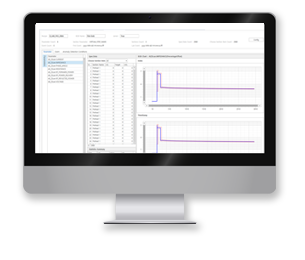

QUICK SETUP

No-Code Easy Setup

QUICK SETUP

No-Code Easy Setup

- 1000+ Parameters

- 1000+ Events

- Every Alarm

- Data Source Configuration

- Definition of Virtual Parameters / Events

- Data Classification and Filter Settings

- Configuration of Data Context, Alias, and Dataset Packaging

- Target Value, LSL, USL Pattern for 150 Parameters

- Anomaly Detection Conditions

Easy Integration

Feed into your projects

Easy Integration

Feed into your projects

Dataset Notifications

Equal=A Data Processor notifies dataset information through Redis once a dataset is created. To receive real-time dataset creation notifications, use the Redis Subscription information defined in the Data Process Workflow.

Search APls

We provide a series of APIs that allow you to search for fingerprint data based on context conditions such as time period, RecipeID, LotID, and Wafer No. These APIs can be easily integrated into custom-built analytical systems.

Analysis Result Notifications

You can receive notifications immediately upon the generation of dataset analysis results. These results can be utilized for creating custom dashboards or for real-time interlocks and other follow-up actions.

Download APls

The retrieved fingerprint data is generated in various sizes depending on the process length, and the size of BOB data also varies. The Pattern FDC server manages the fingerprint data and introduces a method to receive encrypted BOB and fingerprint data through the Download API.

PARTNERS

BUSINESS PARTNERS

PARTNERS

We sincerely thank our valued customers for trusting Doople's technology and services. We will continue to deliver exceptional customer satisfaction through relentless innovation and challenges.

BUSINESS PARTNERS

PARTNERS

We sincerely thank our valued customers for trusting Doople's technology and services. We will continue to deliver exceptional customer satisfaction through relentless innovation and challenges.