Equal=A Data Platform

MANUFACTURING BIG DATA PLATFORM

Real-time Process Data Preprocessing and Process Pattern Analysis Solution

It is a data service platform that performs real-time data preprocessing to enable Plug-and-Play integration of equipment data in the analysis system. Datasets generated in real time based on process contexts can be easily utilized.

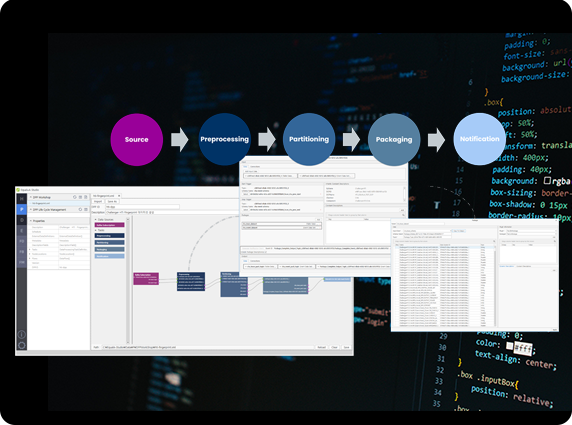

DATA PROCESSING FLOWS

Data Processing Flow Design

You can define a Data Processing Plan (DPP) to outline the flow of data processing. This includes defining real-time data flows for data reception, virtual sensors, virtual event definitions, data classification, dataset generation, and loading.

DEPLOY & MANAGE DATA PROCESSING FLOWS

Data Processing Flow Deployment and Management

You can deploy Data Processing Plans (DPPs) and toggle their activation on or off. Existing DPPs in use can be downloaded for sharing, modified, and redeployed as needed.

REAL-TIME DATA PROCESSOR

For Your Flexible Analytics, We Provide Indispensable Features

REAL-TIME DATA PROCESSOR

For Your Flexible Analytics, We Provide Indispensable Features

Virtual Sensors & Events

You can generate virtual sensor data using real-time Trace, Event, and Exception data. It is possible to detect changes in Trace data to trigger events, combine real-time data to create new events, and perform real-time encoding, such as converting string values into integers.

Record Partitioning

Data transmitted according to a single Collection Plan can be classified and restructured. New data streams can be created by reorganizing desired parameters or events. This enables data collection tailored to analysis purposes without modifying equipment metadata or the Data Collection Plan (DCP).

Context Extraction

In a series of data processing steps, the context of the data can be extracted and provided along with the output data. This context data can be used as conditions for the next stage of data processing and can also be utilized for analysis.

Alias Mapping

The names of parameters and events defined in the equipment metadata are determined during the manufacturing stage. However, even for the same parameter, different names may be assigned. In the analysis stage, where data is utilized, different names may be required. The alias mapping feature will accelerate the utilization of data.

Dataset Packaging

As long as there are events indicating the start and end, datasets can be completed in real-time. By effectively utilizing Virtual Events and Record Partitioning, datasets can be created in real-time without additional post-processing. Imagine a dataset that is finalized the moment the end event is triggered.

Dataset Description

Datasets are provided in a table format consisting of multiple columns with names and value types. Along with this dataset structure information, such as Equal=A, a standardized Dataset Description that includes context information is provided with the data. This facilitates the construction of data storage, management, and analysis systems.

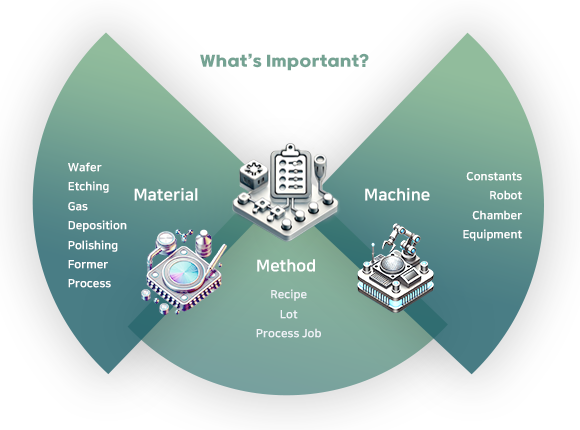

Equal=A Pattern FDC

CONTEXT BASED DATASET MANAGEMENT

Context-Based Process Dataset Management

Datasets are managed based on context information such as Equipment ID, Chamber ID, Lot ID, and Recipe ID. This allows you to quickly find data corresponding to the desired process context. Multiple equipment datasets can be downloaded for easy comparison and detailed analysis on a work PC.

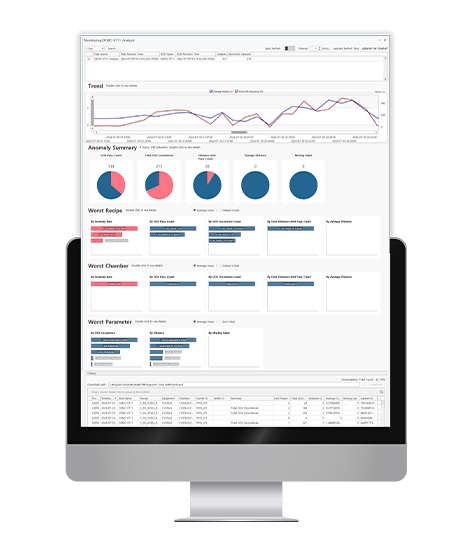

REAL-TIME MONITORING & DASHBOARD

Real-Time Anomaly Detection and Dashboard

Provides methods to create ideal pattern data and upper/lower limit pattern data for each process, enabling the estimation of anomalies in process data patterns. By registering and activating analysis tasks, anomaly detection can be continuously performed while the equipment is in operation. The anomaly detection results are stored in a database and can be monitored through a dashboard.

PATTERN FDC

For Your Flexible Analytics, We Provide Indispensable Features

PATTERN FDC

For Your Flexible Analytics, We Provide Indispensable Features

Fingerprint Dataset Management

Provides dataset management functionality based on context information such as Equipment ID, Chamber ID, Lot ID, and Recipe ID. Users can download desired equipment data for comparative analysis. Sensor data and event data generated during the process are consolidated and managed together.

Runtime Analysis using BOB

BOB can be deployed to the target system or selectively used for real-time anomaly detection analysis. Real-time anomaly detection tasks can be toggled on or off, and a Context Filter feature is provided to filter out unsuitable data.

BOB Generation

BOB (Best of Blood) refers to equipment demonstrating ideal performance. However, in PatternFDC, BOB is used to describe the combined management of individual sensors' ideal patterns along with their upper and lower limit patterns. This BOB data can be created by analyzing pre-collected sample fingerprint data using various statistical methods. BOB is created and utilized only for key process steps.

Dataset Visualization

Provides data visualization features necessary for data verification. It allows basic time-series pattern inspection and comparison by context and parameter, as well as offering various functionalities for basic statistical analysis.

Anomaly Detection

Provides intuitive analysis capabilities based on how closely the data matches the ideal patterns in BOB and the extent of deviation from the upper and lower limit patterns. This enables anomaly detection based on data patterns generated during Recipe execution.

Anomaly Dashboard

Anomaly detection results can be easily monitored through the dashboard, focusing on outliers. It provides process trend changes over time based on similarity and specification exceedance as process metrics. Rankings are also available based on contexts such as Recipe and Chamber.