SEMI EDA STANDARD

A Family Solution Fully Implementing the EDA Standard

Infini-A is a family solution that fully implements the SEMI EDA Standard. It standardizes data generated from equipment and completes the data collection framework across the entire factory system as a comprehensive data service platform.

SEMI EDA Solution

Infini-A

SEMI EDA Solution

Infini-A

The Only One in the World

The world's only Fab-Wide EDA Host Architecture provider, serving IC makers such as Samsung Electronics and SK Hynix.

EDA Total Solution

Enhancing Work Efficiency through EDA Total Solution (Evaluation Tool, Simulator, Monitor, Test Tool)

The World's Largest

Extensive on-site experience and expertise accumulated through setup and operation of the world's largest single production line.

Infini-A Host

EDA CLIENT SOLUTION

Infini-A Host

The Infini-A Host is an EDA client solution that fully implements the SEMI EDA Standard, collecting data from Fab-Wide equipment and delivering it to analytical systems.

EDA CLIENT SOLUTION

Infini-A Host

The Infini-A Host is an EDA client solution that fully implements the SEMI EDA Standard, collecting data from Fab-Wide equipment and delivering it to analytical systems.

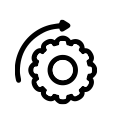

Fab-Wide Data Collection Platform

- Provides a Fab-Wide EDA client architecture

- Proven stability in the world’s largest production lines

- Efficient data session management based on a unique architecture

- Supports interface integration with various analytical systems

Securing a Total Solution for Successful EDA Implementation

- EDA Client System (Infini-A Host)

- Integrated Resource Management and Failover System within Fab (Infini-A MAS)

- Automated EDA Function Verification (Infini-A EvE)

- EDA Server Product for Equipment (Infini-A Integrator)

- Support for PLC and OPC UA Integration for Auxiliary Equipment Data Collection (Infini-A SUB)

Infini-A EQ

EDA SERVER SOLUTION

Infini-A EQ

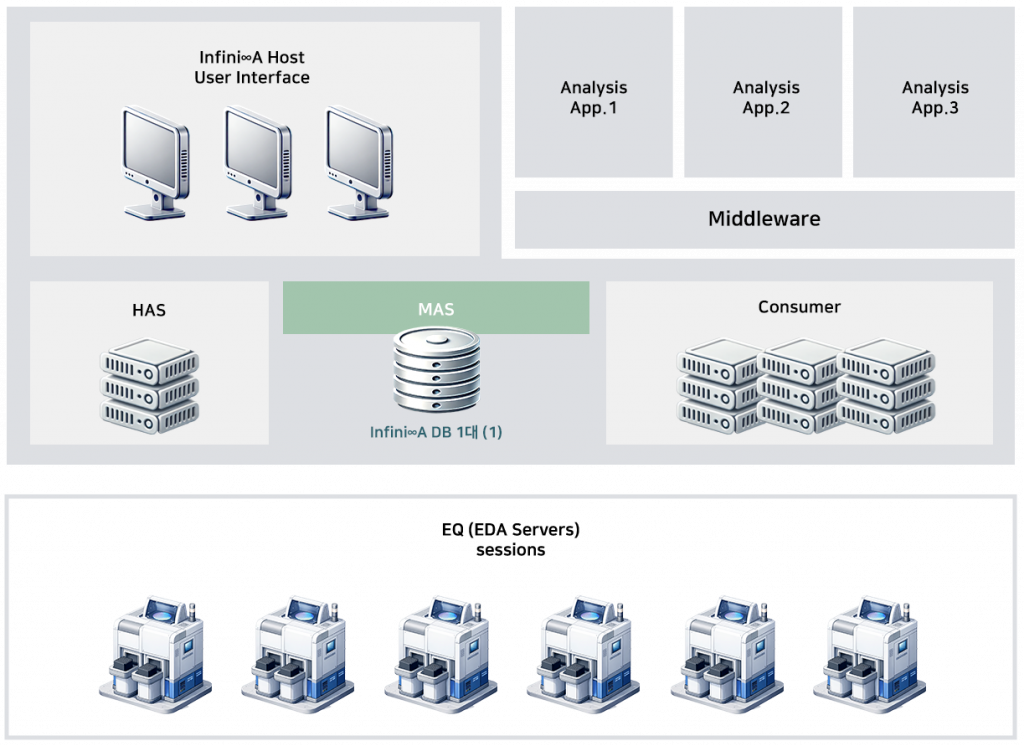

Infini-A EQ is an EDA server that fully implements the SEMI EDA Standard, delivering all data generated from equipment to the factory system (EDA Client) through a standardized protocol.

EDA SERVER SOLUTION

Infini-A EQ

Infini-A EQ is an EDA server that fully implements the SEMI EDA Standard, delivering all data generated from equipment to the factory system (EDA Client) through a standardized protocol.

- Regardless of semiconductor equipment type or process, all data can be represented as metadata with a hierarchical structure that matches the equipment's architecture.

- Manages access permissions for all data access from the equipment.

- Provides user-requested data through standard DCP, ensuring easy data acquisition at any time.

- Supports representation of data from all types of equipment, not limited to semiconductor equipment.

- Secures references for various equipment types from the world's largest semiconductor factories.

- E120, E125, E132, E134, and supplementary standards (E128, E138, E164)

- Continuous development of solutions, including EDA Server (Infini A-EQ), Client (Infini A-Host), Evaluation Tools, and various Fieldbus-compatible solutions

- Provides High-Speed Socket Library API

- Enables distributed processing of module-specific data, including CTC, PMC, and TMC

- Handles input of 80,000 parameters/sec and output of 30,000 parameters/sec with stability

- Real-time validation of modeled metadata based on EDA standard schema

- Simultaneous modeling for multiple equipment projects (Copy & Paste functionality)

- Provides simplified features for direct XML input and modeling tasks

- Supports one-click Metadata Upload > Migration

- Enhances Integrator performance through a simplified Web Service Platform

- Enables remote monitoring and control of servers via the EDA Host

- Provides a remote Manager UI to enable on-site engineers to monitor and operate the EDA Server status

Infini-A EvE

EDA COMPLIANCE TESTING

Infini-A EvE

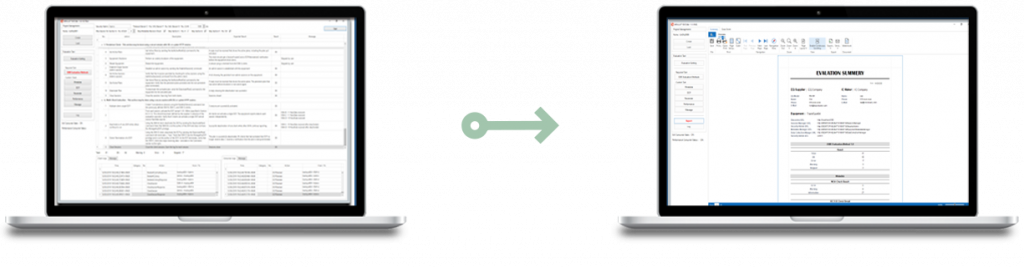

Infini-A EvE is a validation tool that automates the inspection of SEMI EDA standard compliance for semiconductor equipment. It significantly reduces the cost of EDA server software verification during pre-delivery or setup phases.

- Ensures software reliability by validating EDA performance and specifications before equipment delivery

- Drastically reduces verification procedures and time during the equipment setup phase (cost savings)

- Builds customer trust through standardized validation result reports following self-verification

INFINI-A EVE

Evaluation Tool Kit of EDA

INFINI-A EVE

Evaluation Tool Kit of EDA

STEP1. EDA Function & Scenario Test

Function & Scenario Test Based on "ISMI Evaluation Method 1.0"

STEP2. Metadata Verification

NIST MCA(Metadata Conformance Analysis) Verification +

IC Maker Requirement

STEP3. DCP Verification

Is the DCP registered in the customer's (IC Maker) legacy system valid on the equipment?

STEP4. Parameter Value Check

STEP5. Performance Test

Ensuring Message Order, Maintaining Interval Between Messages

(Identifying Messages Exceeding Tolerance), HTTP Option Check

- Extreme Performance Test Utilizing Multiple DCPs

STEP6. Report

Generate and Provide Summary Reports of Test Results (PDF, Spreadsheet)